MPH Series of Cone Crusher High capacity Thanks to the combination of higher speed and throw, which increases the machines power rating and throughput capacity. MPH series of cone crushers have the highest capacities for the size in the ind

进料粒度:

生产能力:

适用物料:

| MPH3 | MPH4 | MPH6 | MPH20 | MPH30 | MPH40 | MPH50 | MPH80 | |

| Motor Power(kw) | 250 | 315 | 500 | 132 | 250 | 315 | 400 | 600 |

| Weight(kg) | 17600 | 25800 | 45400 | 12160 | 18100 | 25600 | 37000 | 64100 |

| Max Feeding | 220mm | 252mm | 330mm | 185mm | 241mm | 304mm | 351mm | 353mm |

| Capacity(t/h) | 94 - 388 | 136 - 565 | 220 - 785 | 93 - 250 | 112 -436 | 136 - 626 | 170 - 786 | 256 -1196 |

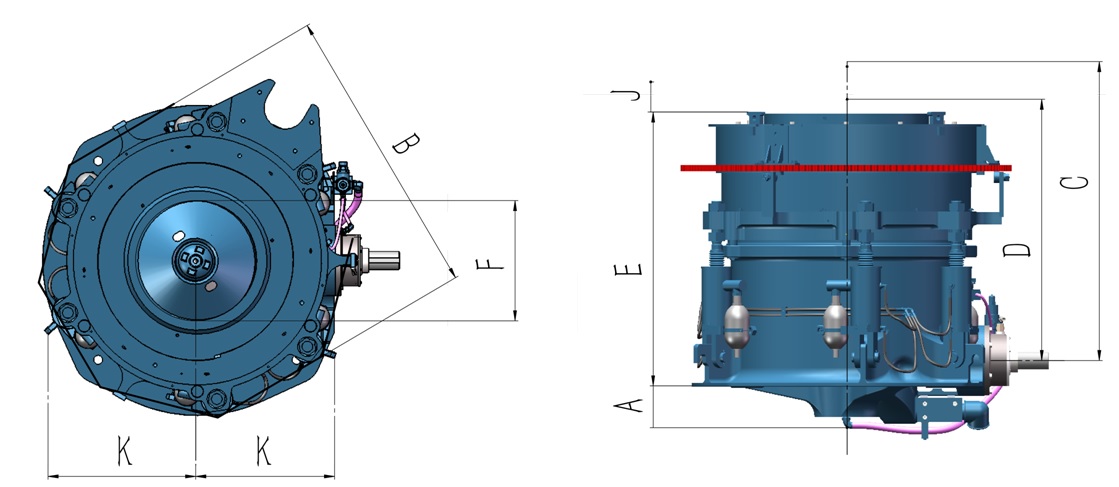

| Dimensions(mm) | MPH20 | MPH30 | MPH40 | MPH50 | HP80 | |

| A:To the bottom of hose | 297 | 328 | 240 | 425 | 722 | |

| B:Max diameter of Adjustment Ring | 1952 | 2207 | 2370 | 2730 | 3500 | |

| C:Space needed to dismantle Transmission Shaft parts | 1840 | 2020 | 2470 | 2650 | 3450 | |

| D:To the bottom of Transmission Shaft | 1160 | 1347 | 1645 | 1760 | 2225 | |

| E:The max height to the top | 1630 | 1865 | 2055 | 2290 | 3335 | |

| F:Inner diameter of feeding | 914 | 1078 | 1308 | 1535 | 1863 | |

| Space needed to move out concave parts | 2140 | 2470 | 2650 | 3300 | 4210 | |

| Space needed to move out mantle parts | 2165 | 2455 | 2715 | 3165 | 3845 | |

| J:Upward displacement of hopper when cleaning chamber | 70 | 85 | 150 | 125 | 159 | |

| K:Location of Anchor Bolt | 545 | 660 | 830 | 882 | 1130 | |

| Diameter of Main Frame discharge | 1240 | 1470 | 1726 | 2040 | 2356 | |

| Model | Crusher chamber | Standard type | Short-headed type | ||

|

discharge |

CSS B2 |

discharge A1 |

CSS B2 |

||

| MPH20 | Fine | 13mm | 95mm | 5mm | 26mm |

| Medium | 17mm | 125mm | 6mm | 55mm | |

| Coarse | 19mm | 185mm | 10mm | 78mm | |

| Extra Coarse | 25mm | 142mm | |||

| MPH30 | Fine | 13mm | 107mm | 6mm | 26mm |

| Medium | 17mm | 150mm | 8mm | 53mm | |

| Coarse | 19mm | 211mm | 10mm | 77mm | |

| Extra Coarse | 25mm | 233mm | |||

| MPH40 | Fine | 14mm | 111mm | 6mm | 51mm |

| Medium | 20mm | 198mm | 8mm | 52mm | |

| Coarse | 25mm | 252mm | 10mm | 92mm | |

| Extra Coarse | 30mm | 299mm | |||

| MPH50 | Fine | 16mm | 133mm | 8mm | 52mm |

| Medium | 20mm | 204mm | 10mm | 57mm | |

| Coarse | 25mm | 286mm | 13mm | 95mm | |

| Extra Coarse | 30mm | 335mm | |||

| MPH80 | Fine | 16mm | 219mm | 5mm | 33mm |

| Medium | 25mm | 267mm | 10mm | 92mm | |

| Coarse | 32mm | 297mm | 13mm | 155mm | |

| Extra Coarse | 32mm | 375mm | |||

| MPH20 | MPH30 | MPH40 | MPH50 | MPH80 | |

| Total Weight | 10400kg | 15810kg | 23000kg | 33150kg | 64100kg |

| Concave, Concave Liner, Adjustment Cap, Hopper | 2680kg | 3525kg | 4800kg | 7200kg | 15210kg |

| Mantle, Mantle Liner and Feeding Plate | 1200kg | 2060kg | 3240kg | 5120kg | 9300kg |

| Max Recommended Power | 132KW | 200KW | 315KW | 400KW | 600KW |

| Rotating Speed of Transmission Shaft | 750-1200 | 700-1200 | 700-1000 | 700-950 | 700-950 |