NS and NH series high-speed cone crusher is developed especially for your needs as the owner or manager of drilling mineral. According to the proven crushing concepts and professional knowledge from the Swedish consultants, the series intro

进料粒度:

生产能力:

适用物料:

| Model | NH200 | NH300 | NH400 | NH600 | NH700 | NH800 | NS200 | NS300 | NS400 | NS600 |

| Max Feeding (mm) | 135 | 185 | 215 | 275 | 300 | 370 | 240 | 360 | 450 | 560 |

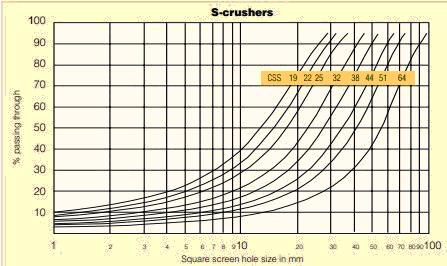

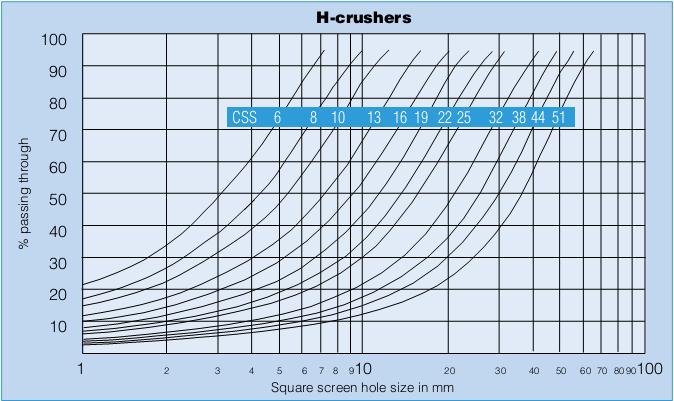

| CSS Range (mm) | 4-35 | 5-38 | 6-44 | 10-51 | 10-70 | 8-70 | 19-38 | 19-51 | 25-54 | 38-83 |

| Weight (kg) | 5300 | 9200 | 14300 | 23500 | 50000 | 66500 | 6800 | 12000 | 19300 | 36500 |

| Motor Power (kw) | 90 | 132 | 250 | 315 | 630 | 600 | 90 | 160 | 250 | 315 |

| Capacity (t/h) | 26-131 | 49-207 | 96-375 | 162-653 | 282-1460 | 310-2120 | 70-166 | 90-350 | 195-598 | 352-1054 |

|

model |

Installed Power |

Chamber |

Max feed size |

Nominalcapacity in t/h with crusher running at css mm |

|

|||||||||||||||

|

KW |

|

mm |

19 |

22 |

25 |

29 |

32 |

35 |

38 |

41 |

44 |

48 |

51 |

54 |

60 |

64 |

70 |

76 |

83 |

|

|

NS200 |

90 |

EC |

240 |

|

83 |

90-112 |

100-156 |

105-166 |

112-141 |

120 |

|

|

|

|

|

|

|

|

|

|

|

C |

200 |

69 |

75-93 |

80-126 |

87-111 |

95 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

NS300 |

150 |

EC |

360 |

|

|

123 |

135-171 |

142-228 |

154-290 |

160-308 |

171-325 |

180-341 |

195-300 |

203-255 |

210 |

|

|

|

|

|

|

C |

300 |

|

106 |

115-144 |

125-197 |

133-251 |

140-268 |

150-281 |

160-300 |

166-261 |

105 |

|

|

|

|

|

|

|

||

|

MC |

235 |

90 |

96-120 |

105-163 |

115-215 |

120-231 |

130-243 |

138-260 |

145-271 |

152-240 |

162 |

|

|

|

|

|

|

|

||

|

NS400 |

220 |

EC |

450 |

|

|

|

|

|

266 |

280-350 |

295-443 |

310-561 |

330-598 |

347-520 |

360-451 |

|

|

|

|

|

|

C |

400 |

|

|

|

222 |

237-298 |

252-380 |

267-482 |

281-510 |

296-442 |

316-397 |

330 |

|

|

|

|

|

|

||

|

MC |

300 |

|

|

193 |

211-265 |

220-340 |

238-431 |

252-460 |

263-482 |

281-424 |

301-371 |

311 |

|

|

|

|

|

|

||

|

NS600 |

315 |

EC |

560 |

|

|

|

|

|

|

|

342 |

362-454 |

391-586 |

407-716 |

425-853 |

463-927 |

485-977 |

523-1046 |

560-981 |

601 |

|

C |

500 |

|

|

|

|

|

|

313 |

333-418 |

351-616 |

3775-751 |

393-785 |

409-821 |

443-891 |

471-824 |

501-635 |

|

|

||

| model | Installed Power | Chamber | Max feed size | Nominalcapacity in t/h with crusher running at css mm | |||||||||||||||

| KW | mm | 4 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | ||

| NH200 | 90 | EC | 135 | 43 | 49-82 | 51-90 | 52-97 | 61-103 | 65-110 | 73-125 | |||||||||

| C | 90 | 41-51 | 43-87 | 47-93 | 52-101 | 55-109 | 59-119 | 68 | |||||||||||

| M | 65 | 35-39 | 35-71 | 41-79 | 43-75 | 47-55 | |||||||||||||

| MF | 50 | 33 | 35-66 | 39-69 | 42-65 | 45-51 | |||||||||||||

| F | 38 | 25-31 | 27-48 | 29-51 | 30-55 | 33-47 | 35 | ||||||||||||

| EF | 29 | 30-40(80% less than4.5-5.5mm) | |||||||||||||||||

| NH300 | 150 | EC | 185 | 67-105 | 75-148 | 77-160 | 84-170 | 90-180 | 103-203 | 113-205 | |||||||||

| C | 145 | 63-130 | 68-139 | 75-149 | 78-160 | 83-171 | 95-194 | 106-146 | |||||||||||

| MC | 115 | 55 | 61-138 | 63-150 | 71-160 | 75-170 | 779-183 | 92-144 | |||||||||||

| M | 90 | 63-83 | 67-129 | 72-139 | 78-151 | 83-161 | 88-152 | 101 | |||||||||||

| MF | 75 | 58 | 62-105 | 67-113 | 72-121 | 80-125 | 85-112 | 91 | |||||||||||

| F | 50 | 45-75 | 50-82 | 42-86 | 56-93 | 52-102 | 65-102 | 61-94 | 75 | ||||||||||

| EF | 35 | 70-90(80% less than5-5.6mm) | |||||||||||||||||

| NH400 | 220 | EC | 215 | 110-196 | 117-271 | 130-293 | 137-312 | 156-353 | 174-394 | 190-382 | |||||||||

| C | 175 | 100 | 108-217 | 115-290 | 123-310 | 130-329 | 150-377 | 162-330 | 181-227 | ||||||||||

| MC | 140 | 95-120 | 103-259 | 112-281 | 117-298 | 125-317 | 143-325 | 160-241 | |||||||||||

| M | 110 | 113-183 | 123-275 | 135-297 | 142-315 | 153-338 | 173-278 | 189 | |||||||||||

| MF | 85 | 112 | 122-225 | 131-242 | 141-260 | 151-279 | 161-297 | 184-246 | |||||||||||

| F | 70 | 87-132 | 92-172 | 103-189 | 110-204 | 118-219 | 126-233 | 135-249 | 153-205 | ||||||||||

| EF | 38 | 100-125(80% less than6-7.5mm) | |||||||||||||||||

| NH600 | 315 | EC | 275 | 172 | 189-337 | 201-434 | 213-462 | 243-544 | 271-604 | 295-659 | 325-508 | ||||||||

| CX | 245 | 172-192 | 184-371 | 198-486 | 210-517 | 240-590 | 265-651 | 291-519 | 321-357 | ||||||||||

| C | 215 | 170-189 | 181-364 | 193-477 | 205-506 | 235-579 | 261-641 | 285-509 | 315-351 | ||||||||||

| MC | 175 | 160-251 | 172-424 | 184-453 | 192-478 | 223-549 | 246-496 | 270-361 | |||||||||||

| M | 135 | 194-292 | 206-435 | 223-467 | 238-498 | 271-500 | 300-401 | ||||||||||||

| MF | 115 | 190 | 203-365 | 220-394 | 233-420 | 250-447 | 284-446 | 315-359 | |||||||||||

| F | 85 | 192-301 | 208-326 | 223-350 | 237-371 | 252-399 | 288-397 | 320 | |||||||||||

| EF | 65 | 207-288 | 225-314 | 242-295 | 259-287 | ||||||||||||||

| NH700 | 500 | EC | 300 | 445-585 | 475-847 | 541-965 | 593-1067 | 653-1167 | 723-1287 | 780-1391 | 845-1508 | 903-1328 | |||||||

| C | 240 | 402 | 430-632 | 458-890 | 523-1016 | 577-1121 | 632-1227 | 698-1354 | 753-1461 | 816-1457 | 873-1283 | ||||||||

| MC | 195 | 377-436 | 402-721 | 429-832 | 489-949 | 540-1050 | 593-1150 | 654-1267 | 705-1368 | 768-1365 | 818-1201 | ||||||||

| M | 155 | 398-558 | 426-781 | 452-831 | 520-949 | 569-1049 | 628-1149 | 689-1266 | 742-1367 | 807-1243 | 861-1093 | ||||||||

| MF | 100 | 373-419 | 400-711 | 432-760 | 459-809 | 524-923 | 580-937 | 639-784 | 700 | ||||||||||

| F | 90 | 354-390 | 380-651 | 4011-699 | 439-747 | 466-795 | 535-907 | 589-852 | 646-713 | ||||||||||

| EF | 80 | 277-400 | 303-512 | 325-553 | 349-593 | 373-634 | 398-675 | 452-770 | 501-723 | 548-664 | |||||||||

| NH800 | 600 | EC | 370 | 476-635 | 546-1272 | 602-1406 | 659-1541 | 727-1697 | 785-1832 | 852-1989 | 909-2123 | ||||||||

| C | 330 | 538-767 | 612-1227 | 677-1357 | 743-1487 | 818-1638 | 882-1768 | 960-1919 | 1023-1608 | ||||||||||

| MC | 260 | 538 | 573-859 | 654-1226 | 722-1356 | 791-1485 | 873-1637 | 942-1766 | 1022-533 | 1092-1226 | |||||||||

| M | 195 | 548-608 | 583-1038 | 667-1184 | 738-1309 | 807-1435 | 890-1581 | 960-1599 | 1042-1388 | 1112 | |||||||||

| MF | 130 | 512 | 545-928 | 582-988 | 663-1127 | 732-1246 | 802-1365 | 885-1415 | 955-1240 | ||||||||||

| F | 120 | 528 | 569-827 | 606-883 | 646-940 | 736-980 | 813-880 | ||||||||||||

| EFX | 100 | 399-497 | 430-626 | 463-673 | 493-719 | 525-765 | 598-798 | 662-716 | |||||||||||

| EF | 85 | 361-415 | 392-527 | 422-569 | 454-611 | 487-653 | 518-695 | 591-793 | 652-877 | 716-878 | 788 | ||||||||

| EEF | 75 | 307-351 | 326-436 | 353-474 | 381-512 | 409-549 | 437-587 | 465-625 | 530-570 | ||||||||||

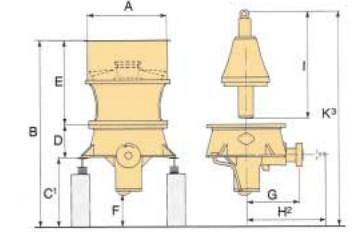

| size (mm) | NS200 | NS300 | NS400 | NS600 | NH200 | NH300 | NH400 | NH600 | NH700 | NH800 |

| A | Ø1285 | Ø1635 | Ø2000 | Ø2800 | Ø1078 | Ø1360 | Ø1540 | Ø1954 | Ø2450 | Ø2660 |

| B | 2902 | 3485 | 4075 | 5100 | 2560 | 2992 | 3410 | 4215 | 5475 | 6456 |

| C1 | 1020 | 1125 | 1300 | 1600 | 1020 | 1125 | 1300 | 1600 | 2200 | 2870 |

| D | 540 | 665 | 745 | 860 | 540 | 655 | 745 | 860 | 1228 | 1186 |

| E | 1342 | 1705 | 2030 | 2640 | 1000 | 1212 | 1365 | 1755 | 2045 | 2400 |

| F | 400 | 422 | 452 | 631 | 400 | 422 | 452 | 631 | 998 | 1151 |

| G | 843 | 1061 | 1280 | 1497 | 843 | 1061 | 1280 | 1497 | 1824 | 2073 |

| H2 | 1270 | 1705 | 1900 | 2156 | 1270 | 1705 | 1900 | 2156 | 2850 | 3100 |

| I | 1703 | 2050 | 2420 | 2895 | 1425 | 1688 | 1985 | 2344 | 3095 | 3545 |

| K3 | 3600 | 4250 | 4930 | 5355 | 3000 | 3570 | 4000 | 4835 | 6600 | 7770 |

| NS200 | NS300 | NS400 | NS600 | NH200 | NH300 | NH400 | NH600 | NH700 | NH800 | |

|

Heaviest lift during maintenance |

2300 | 5100 | 8100 | 16500* | 1400** | 2900** | 4700** | 7400** | 13200** | 22000** |

| Weight (kg) | 6800 | 12000 | 19300 | 35000 | 5300** | 9200** | 14300** | 23500** | 49950** | 70000** |