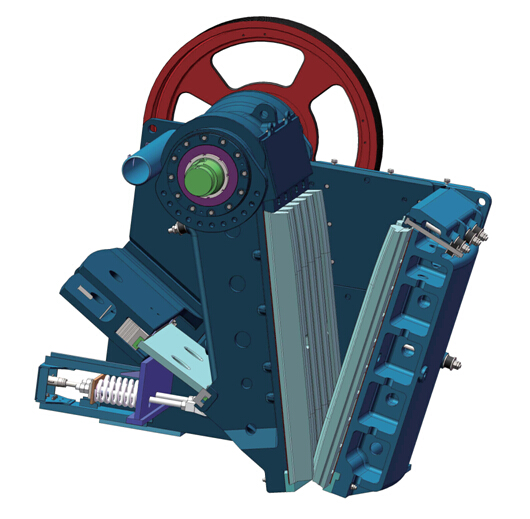

MJ jaw crushers are of single-elbow compound swing type and heavy-duty design, using symmetric deep crushing chamber, big feed opening and optimized meshing angle to achieve high operation rate, large crushing ratio and high productivity. Wi

进料粒度:

生产能力:

适用物料:

| Model | MJ4090 | MJ4120 | MJ6120 | MJ6130 | MJ6150 | MJ8150 |

| Feeding Size | 895×660 | 1200×830 | 1200×1100 | 1300×1130 | 1500×1070 | 1500×1300 |

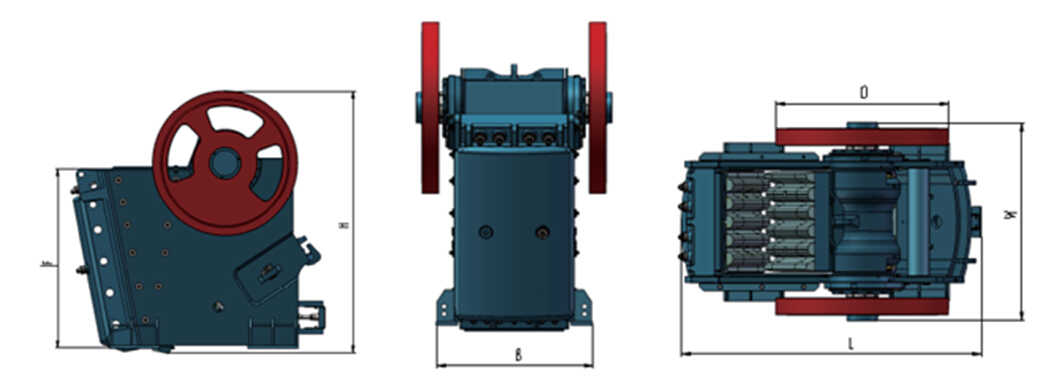

| L(m) | 2.55 | 3.23 | 3.61 | 3.76 | 4.11 | 4.50 |

| W(m) | 1.88 | 2.57 | 2.35 | 2.47 | 3.00 | 2.90 |

| H(m) | 2.38 | 2.95 | 3.51 | 3.85 | 3.33 | 4.19 |

| D(m) | 1.60 | 1.86 | 1.86 | 2.17 | 1.76 | 2.17 |

| F(m) | 1.58 | 1.93 | 2.50 | 2.68 | 2.39 | 3.05 |

| Shipping volume(m³) | 13 | 23 | 32 | 38 | 48 | 58 |

| (CSS)Range | 50-175 | 75-275 | 125-275 | 125-300 | 125-300 | 150-300 |

| Weight(kg) | 13200 | 27000 | 34500 | 41500 | 53000 | 63500 |

| Motor Power(kw) | 75 | 132 | 160 | 160 | 200 | 200 |

| Capacity(t/h) | 85-320 | 240 | 305-800 | 330-965 | 385-1090 | 480-1155 |

| CSS(mm) | Model | |||||

| MJ4090 | MJ4120 | MJ6120 | MJ6130 | MJ6150 | MJ8150 | |

| 40 | ||||||

| 50 | 85-115 | |||||

| 75 | 95-155 | 160-220 | ||||

| 100 | 120-195 | 220-295 | ||||

| 125 | 145-230 | 270-350 | 3295-390 | 330-435 | 385-495 | |

| 150 | 170-270 | 320-435 | 355-460 | 385-500 | 440-595 | 480-620 |

| 175 | 195-315 | 390-510 | 400-525 | 445-570 | 505-670 | 540-705 |

| 200 | 440-575 | 450-590 | 490-645 | 575-745 | 615-805 | |

| 225 | 490-645 | 505-665 | 550-735 | 635-820 | 670-880 | |

| 250 | 555-725 | 555-730 | 605-805 | 705-925 | 745-980 | |

| 275 | 605-795 | 605-800 | 660-880 | 770-1005 | 825-1060 | |

| 300 | 720-965 | 820-1080 | 880-1155 | |||

The capacity shown in the table only indicates an approximation of the capacity of the crusher. The corresponding condi- tions are open-circuit crushing, dry blasting granite with a bulk density of 1600 kg/m3, the maximum size of which can meet the maximum feed size allowed by the crusher. The lower values in the table apply to the circumstance where the fines of the feeding less than the size of the discharge are rejected, and the higher values apply to the circumstance with contents of fines. The CSS that the crusher can operate normally depends on the feeding granularity distribution, the friability of the material (Wi), the amount of feeding contaminants, the type of jaw plates installed, and the type of its material used.

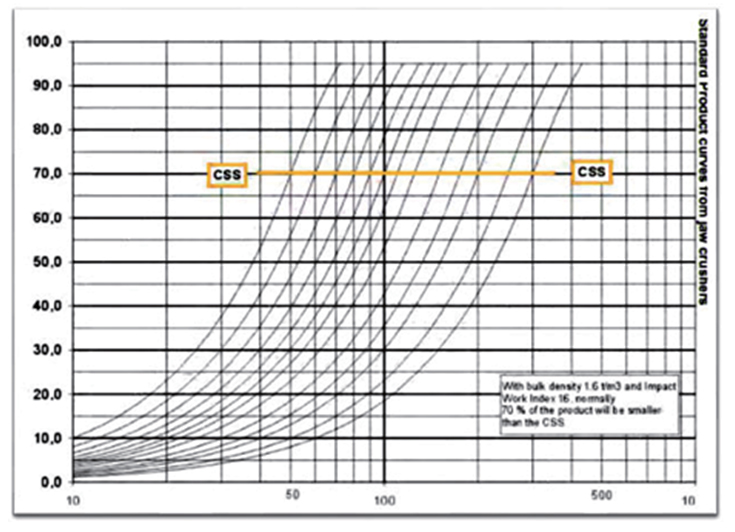

The Characteristic Curve of Discharge Granularity This curve is a typical granularity characteristic curve of medium crushable rock (Crush- ing Work Index Wi=16). About 75% of the products are less than the CSS. The shape and product of the Granularity Curve is less than the ratio of the CSS, depending on the characteristics of the minerals. For rocks with different friability (Wi between 20-12), normally about 65%-85% of the crushed product is less than the crusher CSS.